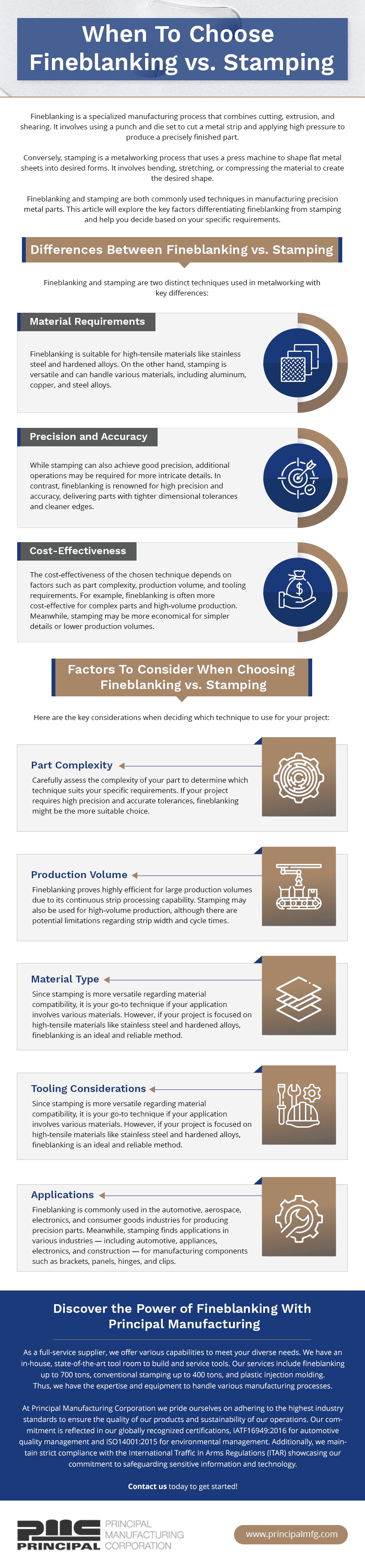

Fineblanking is a specialized manufacturing process that combines cutting, extrusion, and shearing. It involves using a punch and die set to cut a metal strip and applying high pressure to produce a precisely finished part.

Conversely, stamping is a metalworking process that uses a press machine to shape flat metal sheets into desired forms. It involves bending, stretching, or compressing the material to create the desired shape.

Fineblanking and stamping are both commonly used techniques in manufacturing precision metal parts. This article will explore the key factors differentiating fineblanking from stamping and help you decide based on your specific requirements.

Differences Between Fineblanking vs. Stamping

Fineblanking and stamping are two distinct techniques used in metalworking with key differences:

Material Requirements

Fineblanking is suitable for high-tensile materials like stainless steel and hardened alloys. On the other hand, stamping is versatile and can handle various materials, including aluminum, copper, and steel alloys.

Precision and Accuracy

While stamping can also achieve good precision, additional operations may be required for more intricate details. In contrast, fineblanking is renowned for high precision and accuracy, delivering parts with tighter dimensional tolerances and cleaner edges.

Cost-Effectiveness

The cost-effectiveness of the chosen technique depends on factors such as part complexity, production volume, and tooling requirements. For example, fineblanking is often more cost-effective for complex parts and high-volume production. Meanwhile, stamping may be more economical for simpler details or lower production volumes.

Factors To Consider When Choosing Fineblanking vs. Stamping

Here are the key considerations when deciding which technique to use for your project:

Part Complexity

Carefully assess the complexity of your part to determine which technique suits your specific requirements. If your project requires high precision and accurate tolerances, fineblanking might be the more suitable choice.

Production Volume

Fineblanking proves highly efficient for large production volumes due to its continuous strip processing capability. Stamping may also be used for high-volume production, although there are potential limitations regarding strip width and cycle times.

Material Type

Since stamping is more versatile regarding material compatibility, it is your go-to technique if your application involves various materials. However, if your project is focused on high-tensile materials like stainless steel and hardened alloys, fineblanking is an ideal and reliable method.

Tooling Considerations

Fineblanking requires specialized tooling that adheres to tight tolerances, which might involve a higher initial investment. Conversely, stamping provides a flexible range of tooling options and often has comparatively lower upfront costs.

Applications

Fineblanking is commonly used in the automotive, aerospace, electronics, and consumer goods industries for producing precision parts. Meanwhile, stamping finds applications in various industries including automotive, appliances, electronics, and construction for manufacturing components such as brackets, panels, hinges, and clips.

Discover the Power of Fineblanking With Principal Manufacturing

As a full-service supplier, we offer various capabilities to meet your diverse needs. We have an in-house, state-of-the-art tool room to build and service tools. Our services include fineblanking up to 700 tons, conventional stamping up to 400 tons, and plastic injection molding. Thus, we have the expertise and equipment to handle various manufacturing processes.

At Principal Manufacturing Corporation we pride ourselves on adhering to the highest industry standards to ensure the quality of our products and sustainability of our operations. Our commitment is reflected in our globally recognized certifications, IATF16949:2016 for automotive quality management and ISO14001:2015 for environmental management. Additionally, we maintain strict compliance with the International Traffic In Arms Regulations (ITAR) showcasing our commitment to safeguarding sensitive information and technology.

Contact us today to get started!

Comments are closed