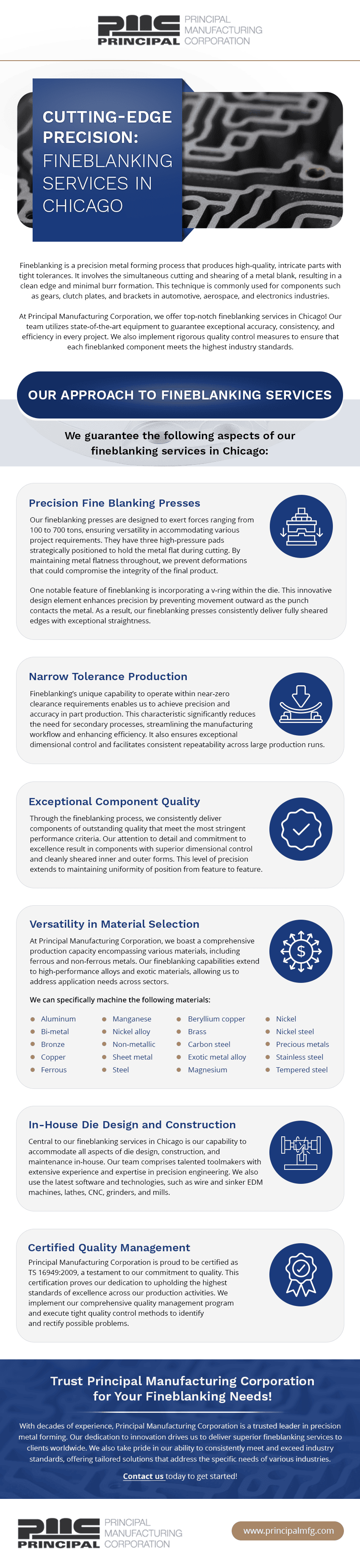

Fineblanking is a precision metal forming process that produces high-quality, intricate parts with tight tolerances. It involves the simultaneous cutting and shearing of a metal blank, resulting in a clean edge and minimal burr formation. This technique is commonly used for components such as gears, clutch plates, and brackets in automotive, aerospace, and electronics industries.

At Principal Manufacturing Corporation, we offer top-notch fineblanking services in Chicago! Our team utilizes state-of-the-art equipment to guarantee exceptional accuracy, consistency, and efficiency in every project. We also implement rigorous quality control measures to ensure that each fineblanked component meets the highest industry standards.

Our Approach to Fineblanking Services

We guarantee the following aspects of our fineblanking services in Chicago:

Precision Fine Blanking Presses

Our fineblanking presses are designed to exert forces ranging from 100 to 700 tons, ensuring versatility in accommodating various project requirements. They have three high-pressure pads strategically positioned to hold the metal flat during cutting. By maintaining metal flatness throughout, we prevent deformations that could compromise the integrity of the final product.

One notable feature of fineblanking is incorporating a v-ring within the die. This innovative design element enhances precision by preventing movement outward as the punch contacts the metal. As a result, our fineblanking presses consistently deliver fully sheared edges with exceptional straightness.

Narrow Tolerance Production

Fineblanking’s unique capability to operate within near-zero clearance requirements enables us to achieve precision and accuracy in part production. This characteristic significantly reduces the need for secondary processes, streamlining the manufacturing workflow and enhancing efficiency. It also ensures exceptional dimensional control and facilitates consistent repeatability across large production runs.

Exceptional Component Quality

Through the fineblanking process, we consistently deliver components of outstanding quality that meet the most stringent performance criteria. Our attention to detail and commitment to excellence result in components with superior dimensional control and cleanly sheared inner and outer forms. This level of precision extends to maintaining uniformity of position from feature to feature.

Versatility in Material Selection

At Principal Manufacturing Corporation, we boast a comprehensive production capacity encompassing various materials, including ferrous and non-ferrous metals. Our fineblanking capabilities extend to high-performance alloys and exotic materials, allowing us to address application needs across sectors.

We can specifically machine the following materials:

- Aluminum

- Beryllium copper

- Bi-metal

- Brass

- Bronze

- Carbon steel

- Copper

- Exotic metal alloy

- Ferrous

- Magnesium

- Manganese steel

- Nickel

- Nickel alloy

- Nickel steel

- Non-metallic

- Precious metals

- Sheet metal

- Stainless steel

- Steel

- Tempered steel

In-House Die Design and Construction

Central to our fineblanking services in Chicago is our capability to accommodate all aspects of die design, construction, and maintenance in-house. Our team comprises talented toolmakers with extensive experience and expertise in precision engineering. We also use the latest software and technologies, such as wire and sinker EDM machines, lathes, CNC, grinders, and mills.

Certified Quality Management

Principal Manufacturing Corporation is proud to be certified as TS 16949:2009, a testament to our commitment to quality. This certification proves our dedication to upholding the highest standards of excellence across our production activities. We implement our comprehensive quality management program and execute tight quality control methods to identify and rectify possible problems.

Trust Principal Manufacturing Corporation for Your Fineblanking Needs!

With decades of experience, Principal Manufacturing Corporation is a trusted leader in precision metal forming. Our dedication to innovation drives us to deliver superior fineblanking services to clients worldwide. We also take pride in our ability to consistently meet and exceed industry standards, offering tailored solutions that address the specific needs of various industries.

Contact us today to get started!