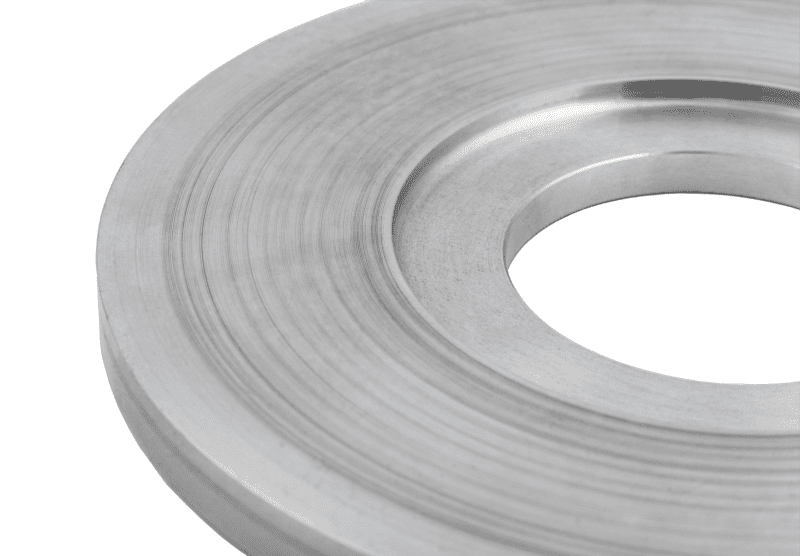

Balance rings are critical components that help balance motors within an assembly. They sit on the base plate of a motor to help assemblers install and position a motor so the movement of the rotor will not destabilize the assembly during operation. Without this hardware, motors could move or come out of alignment when the rotor rotates at high speeds.

At Principal Manufacturing Corporation, we engineer solutions for OEM, automotive, and industrial clients for a variety of applications. Our services include manufacturing and machining for metal and plastic goods, CNC machining, finishing processes, automated assembly, and more. Learn about how we develop our motor balance rings and how to get started with your next project.

Manufacturing Balance Rings for Industry Applications

Various markets use balance rings to stabilize machinery and equipment assemblies that include motors, such as vehicles, industrial manufacturing systems, and consumer washing machines. We assess, develop, and produce balance rings for specific battery electric vehicles, or BEVs, with standard or custom specifications. These products comply with applicable industry standards for materials, strength, and quality control, and we work with automotive companies as well as OEMs.

We’ve built our in-house design and manufacturing processes to create highly precise balance rings that provide long-term support for machinery operations. Our processes include:

- Fineblanking. Fineblanking is a precise manufacturing process that shapes blanks into more complex or specific shapes based on a product’s design specifications. Whereas general metal stamping processes are built to control metal shearing and tearing, fineblanking is a fine-tuned technique designed to minimize tears and variability. The top and bottom of the workpiece are held in place while a cutting tool shapes it using a single stroke. We have fineblanking presses with capacities of up to 700 tons of force. This reduces the risk of misshaping workpieces or weakening the metal.

- Grinding. Balance rings need to fall within tight tolerances to best stabilize motors against the forces that rotating rotors generate. We use different grinding processes, such as double-disc grinding to uphold tolerances of under 0.010mm flatness, to ensure there is no excess material on the workpiece and that each surface is smooth and truly parallel.

- CNC machining. Through our automated, value-added CNC machining processes, we can precisely shape a part, drill or bore holes through rings for fasteners and other critical features, and more.

- End-of-line inspection. Our production processes end with thorough inspections. These ensure the rings are undamaged from the production cycle, adhere to design specifications, and meet or exceed applicable standards.

Project: Motor Balance End Rings

One of our clients worked with another manufacturer initially to produce motor assemblies, but then brought their challenging application to Principal Manufacturing Corporation. The issue, in this case, was receiving aluminum in lengths rather than premade coils. We developed a continuous flow process, building a fineblanking press to fineblank lengths of aluminum sheets and create the final products. Now, we have added this unique capability to our service offerings.

This project involved using aluminum sheeting and shaping it into 155mm x 35mm balance rings for automotive BEVs. Over the course of four weeks, our team of CNC and grinding engineers produced millions of components in cleanroom settings, with a capacity of up to 10 million units, using CNC machining, fineblanking, double-disc grinding, brush deburring, and wash and package procedures. The finished products had a material finish of 1.8 RA and tolerances within 0.015 microns at the tightest points.

Through our comprehensive array of in-house manufacturing and finishing services, we were able to transform the production process and ensure the right components were created from available material formats. Our team performed thickness, micro finish, laser marking, and end-of-line inspections to test that the end products would meet the client’s exact specifications.

Services From Principal Manufacturing Corporation

Turn to Principal Manufacturing Corporation for high-quality production solutions for industrial, automotive, and OEM products. We maintain ISO 14001:2015 and IATF 16949:2016 certifications as part of our continued commitment to quality and innovation in our ready-for-use components and affordable, time-saving services. Contact us today to request a quote or to learn more about our custom project capabilities.