Plastic injection molding is a versatile and cost-effective manufacturing process for producing various plastic parts, from small components to intricate structures. It is highly regarded as one of the most adaptable techniques for creating parts and components in large quantities. Its applications are also widespread, ranging from the automotive and aerospace industries to medical and electronic devices.

In the competitive market of product development, getting the injection molding process right is crucial. Therefore, choosing the right partner is paramount as it can significantly impact every aspect of the project, from quality to profitability.Moreover, working with unqualified contractors may lead to complications. These include extended delays, increased costs, and subpar quality.

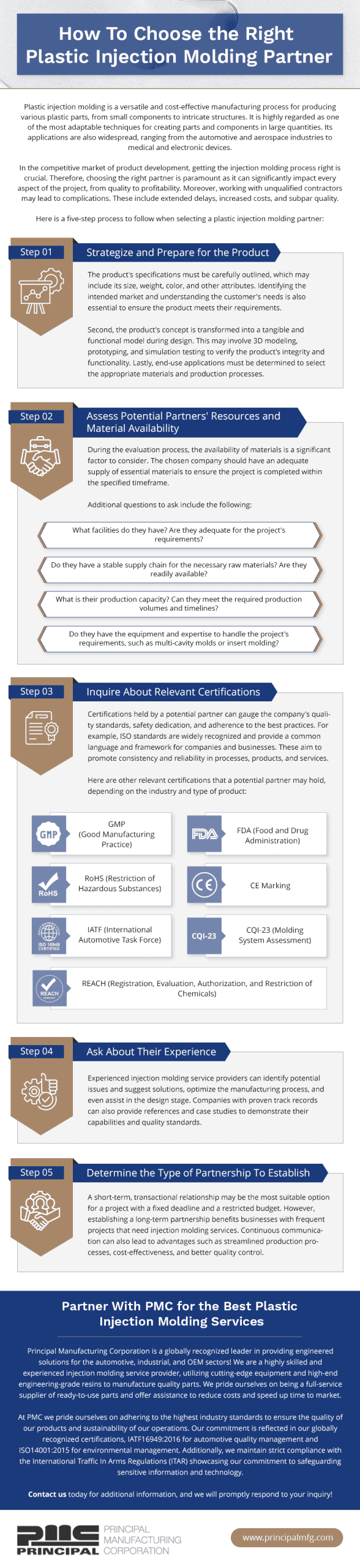

Here is a five-step process to follow when selecting a plastic injection molding partner:

Step 1: Strategize and Prepare for the Product

The product’s specifications must be carefully outlined, which may include its size, weight, color, and other attributes. Identifying the intended market and understanding the customer’s needs is also essential to ensure the product meets their requirements.

Second, the product’s concept is transformed into a tangible and functional model during design. This may involve 3D modeling, prototyping, and simulation testing to verify the product’s integrity and functionality. Lastly, end-use applications must be determined to select the appropriate materials and production processes.

Step 2: Assess Potential Partners’ Resources and Material Availability

During the evaluation process, the availability of materials is a significant factor to consider. The chosen company should have an adequate supply of essential materials to ensure the project is completed within the specified timeframe.

Additional questions to ask include the following:

- What facilities do they have? Are they adequate for the project’s requirements?

- Do they have a stable supply chain for the necessary raw materials? Arethey readily available?

- What is their production capacity? Can they meet the required production volumes and timelines?

- Do they have the equipment and expertise to handle the project’s requirements, such as multi-cavity molds or insert molding?

Step 3: Inquire About Relevant Certifications

Certifications held by a potential partner can gauge the company’s quality standards, safety dedication, and adherence to the best practices. For example, ISO standards are widely recognized and provide a common language and framework for companies and businesses. These aim to promote consistency and reliability in processes, products, and services.

Here are other relevant certifications that a potential partner may hold, depending on the industry and type of product:

- GMP (Good Manufacturing Practice)

- FDA (Food and Drug Administration)

- CE Marking

- RoHS (Restriction of Hazardous Substances)

- REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals)

- IATF (International Automotive Task Force)

- CQI-23 (Molding System Assessment)

Step 4: Ask About Their Experience

Experienced injection molding service providers can identify potential issues and suggest solutions, optimize the manufacturing process, and even assist in the design stage. Companies with proven track records can also provide references and case studies to demonstrate their capabilities and quality standards.

Step 5: Determine the Type of Partnership To Establish

A short-term, transactional relationship may be the most suitable option for a project with a fixed deadline and a restricted budget. However, establishing a long-term partnership benefits businesses with frequent projects that need injection molding services. Continuous communication can also lead to advantages such as streamlined production processes, cost-effectiveness, and better quality control.

Partner With PMC for the Best Plastic Injection Molding Services

Principal Manufacturing Corporation is a globally recognized leader in providing engineered solutions for the automotive, industrial, and OEM sectors! We are a highly skilled and experienced injection molding service provider, utilizing cutting-edge equipment and high-end engineering-grade resins to manufacture quality parts. We pride ourselves on being a full-service supplier of ready-to-use parts and offer assistance to reduce costs and speed up time to market.

At PMC we pride ourselves on adhering to the highest industry standards to ensure the quality of our products and sustainability of our operations. Our commitment is reflected in our globally recognized certifications, IATF16949:2016 for automotive quality management and ISO14001:2015 for environmental management. Additionally, we maintain strict compliance with the International Traffic In Arms Regulations (ITAR) showcasing our commitment to safeguarding sensitive information and technology.

Contact us today for additional information, and we will promptly respond to your inquiry!

Comments are closed