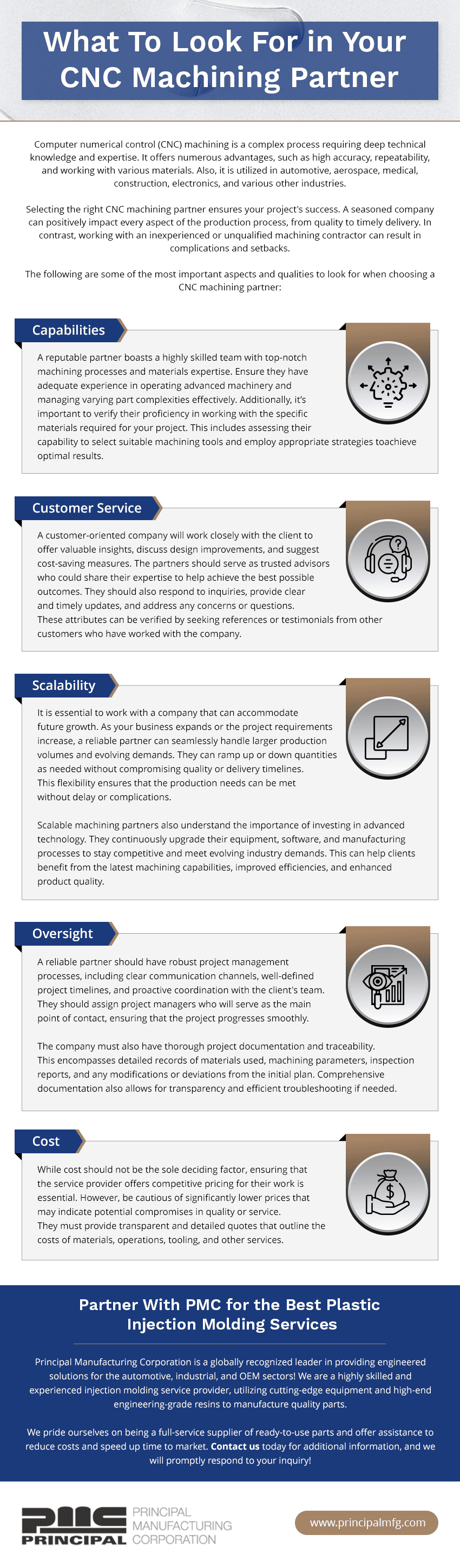

Computer numerical control (CNC) machining is a complex process requiring deep technical knowledge and expertise. It offers numerous advantages, such as high accuracy, repeatability, and working with various materials. Also, it is utilized in automotive, aerospace, medical, construction, electronics, and various other industries.

Selecting the right CNC machining partner ensures your project’s success. A seasoned company can positively impact every aspect of the production process, from quality to timely delivery. In contrast, working with an inexperienced or unqualified machining contractor can result in complications and setbacks.

The following are some of the most important aspects and qualities to look for when choosing a CNC machining partner:

1. Capabilities

A reputable partner boasts a highly skilled team with top-notch machining processes and materials expertise. Ensure they have adequate experience in operating advanced machinery and managing varying part complexities effectively. Additionally, its important to verify their proficiency in working with the specific materials required for your project. This includes assessing their capability to select suitable machining tools and employ appropriate strategies to achieve optimal results.

2. Customer Service

A customer-oriented company will work closely with the client to offer valuable insights, discuss design improvements, and suggest cost-saving measures. The partners should serve as trusted advisors who could share their expertise to help achieve the best possible outcomes. They should also respond to inquiries, provide clear and timely updates, and address any concerns or questions. These attributes can be verified by seeking references or testimonials from other customers who have worked with the company.

3. Scalability

It is essential to work with a company that can accommodate future growth. As your business expands or the project requirements increase, a reliable partner can seamlessly handle larger production volumes and evolving demands. They can ramp up or down quantities as needed without compromising quality or delivery timelines. This flexibility ensures that the production needs can be met without delay or complications.

Scalable machining partners also understand the importance of investing in advanced technology. They continuously upgrade their equipment, software, and manufacturing processes to stay competitive and meet evolving industry demands. This can help clients benefit from the latest machining capabilities, improved efficiencies, and enhanced product quality.

4. Oversight

A reliable partner should have robust project management processes, including clear communication channels, well-defined project timelines, and proactive coordination with the client’s team. They should assign project managers who will serve as the main point of contact, ensuring that the project progresses smoothly.

The company must also have thorough project documentation and traceability. This encompasses detailed records of materials used, machining parameters, inspection reports, and any modifications or deviations from the initial plan. Comprehensive documentation also allows for transparency and efficient troubleshooting if needed.

5. Cost

While cost should not be the sole deciding factor, ensuring that the service provider offers competitive pricing for their work is essential. However, be cautious of significantly lower prices that may indicate potential compromises in quality or service. They must provide transparent and detailed quotes that outline the costs of materials, operations, tooling, and other services.

Trust Principal Manufacturing Corporation for High-Quality CNC Machining Services!

Principal Manufacturing Corporation is a reliable provider of machining services and precision manufacturing, catering to a wide range of industries! We also offer fineblanking, plastic injection molding, and conventional stamping.

At PMC we pride ourselves on adhering to the highest industry standards to ensure the quality of our products and sustainability of our operations. Our commitment is reflected in our globally recognized certifications, IATF16949:2016 for automotive quality management and ISO14001:2015 for environmental management. Additionally, we maintain strict compliance with the International Traffic In Arms Regulations (ITAR) showcasing our commitment to safeguarding sensitive information and technology.

Contact us today to discuss your project requirements!

Comments are closed